Countersinking Tools

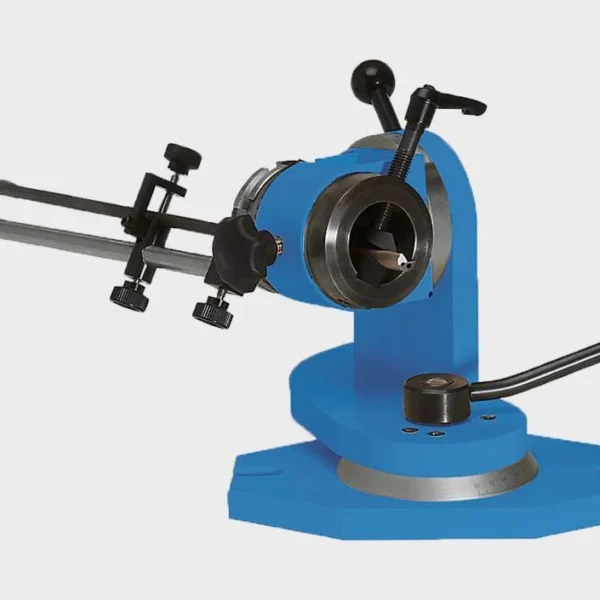

Deburring Tools

Internal and external deburring operations – quick, clean and fully automated

Gühring provides a comprehensive standard range of deburring tools for mechanical finishing hole entry, hole exit and cross hole exit – including the world’s first solid carbide tools for mechanical deburring of hole entry and exit. Instead of time consuming and costly manual work the machining time is reduced with mechanical deburring in a fully automated operating process. Another highlight is the EWR 500, which deburrs cross holes right up to the root.

For the quality of the workpiece – especially with intersecting and cross holes – in particular exit deburring is gaining more and more importance. This applies to, for example, oil galleries in modern high performance engines, where an optimal flow rate is dependent on perfect exit deburring. Highly accurate deburring and producing a chamfer is also increasingly required in crankshafts, valve blocks, steering arms, rotational housings, drive elements, injector nozzles and brake cylinders. Whilst the deburring of the entry of the hole hardly causes a problem, exit deburring of drilled holes in many cases involves an extensive operation that is often carried out manually and is time and cost intensive. Here the latest development, the deburring reamer EWR 500, finds its application.

With a multitude of deburring bits Gühring now offers different possibilities to mechanically resolve the complex requirements. This not only means a considerable cost and time saving for the production, but also, more importantly, improved quality and process reliability. Moreover Gühring offers a deburring milling cutter for external deburring to customer’s specific application tasks.

The spiral HSS-/HSCO countersink SpyroTec offers universal application in almost all materials, with 60 % lower feed force and 50 % lower radial force. The countersink for a round, precise and chatter-free countersink.

Voici le seul résultat