What is carbide?

Carbide is a sintered material, which means that it has been heated under pressure. It is a mixture of various carbides and cobalt. This is why we also use the term sintered carbide metals.

Uses of the carbide drill: Where is carbide used?

Carbide is mainly used as a cutting material for tools such as drills, lathe tools and milling tools. Due to the increased cutting values, tool life and improved drilling quality, carbide tools are ideal for series and large-scale production on CNC machines with stable clamping. However, the purchase price for carbide tools is significantly higher than for HSS tools. Carbide is therefore not always the most economical solution for machining. High-speed steel tools are particularly preferable for use in unstable conditions and with small batch sizes.

What is a solid carbide drill?

With solid carbide drills, the tool body and cutting edges are made of different cutting materials. With a solid carbide drill, on the other hand, the manufacturer produces the entire tool from carbide. Solid carbide drills are suitable for particularly demanding machining tasks where high wear resistance and efficiency are required. The production of a perfect solid carbide drill starts with the composition of the cutting material. That’s why Gühring manufacture their own carbide.

What drills are available?

Gühring produced the first HSS drill in 1898 and has remained true to its beginnings. Our variety of tools is unparalleled on the market. The range of drilling tools includes the following types of drills:

- HSS and solid carbide twist drills

- Step drills, core drills, countersinking drills and countersinks

- Centre drills and NC spot drills

- Micro drills with diameters up to 0.05 mm

- Deep hole drill for diameter/length ratios up to 80xD

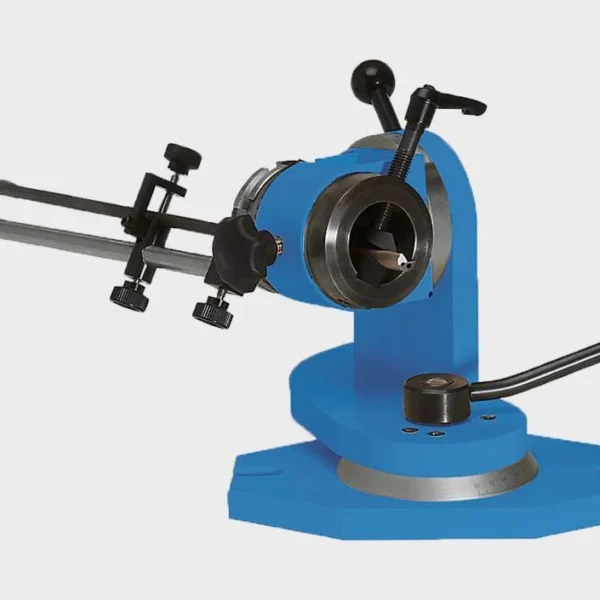

- Interchangeable insert drilling systems

Reviews

There are no reviews yet.