HT 800 WP for machining steel beams

Steel beams are usually prepared for assembly on special drilling/sawing machines. The clamping conditions on these machines are usually unstable. This places particularly high demands on the drilling tools. Gühring offers interchangeable inserts that are specially designed for processing steel beams. The point geometry of these indexable inserts ensures optimum centring properties and thus compensates for the unstable machining conditions. The high point angle in the outer area of the indexable inserts guarantees minimised burr formation.

Gühring has also expanded its range of indexable inserts for machining C-steels. Their stable cutting wedge ensures high wear resistance without increasing the process forces. The concave-shaped cutting edge ensures optimal chip breakage of long-chipping steels.

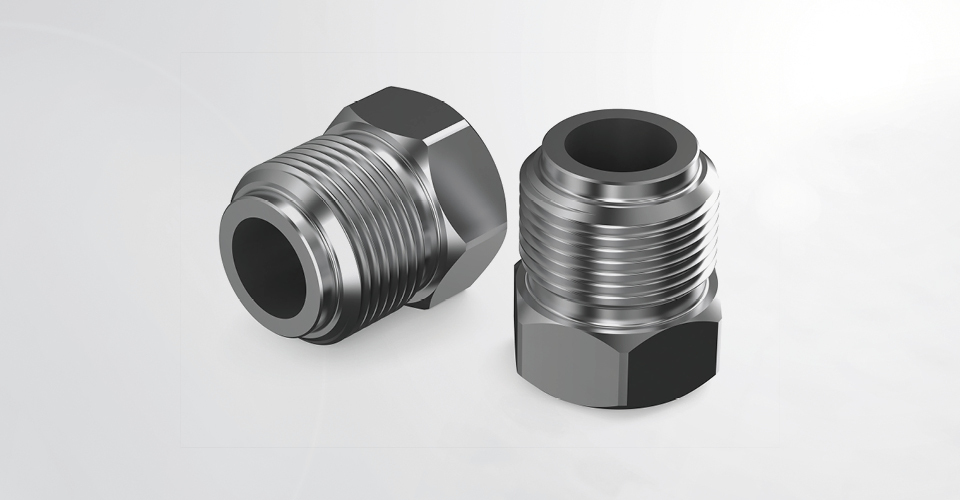

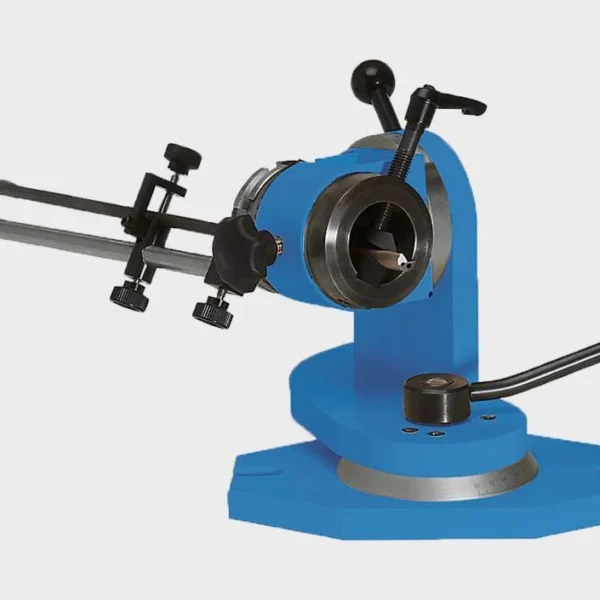

These carbide special drilling tools are based on the HT 800 WP tool system. The HT 800 consists of a wear-resistant steel beam, the replaceable cutting body and a locking screw with clamping principle. Thanks to the pin and fitting hole, the interchangeable insert has minimal play and sits firmly in the carrier. The innovative clamping principle achieves the highest process reliability for holes up to 10 x D. The modular system makes it easy to change inserts directly in the machine. There is no need to change tools or reconfigure the machine afterwards.

The cutting material, geometry and surface of the interchangeable inserts are perfectly matched to the respective area of application. This means that the HT 800 achieves holes of the same quality as a solid carbide drill with an optimised flute profile. The indexable inserts can be used in the standard holders 1xD, 1.5xD, 3xD, 5xD, 7xD and 10xD. In the diameter range from 26.00 to 40.00 mm, the inserts can also be reground.

Interchangeable insert drilling systems for steel processing

Gühring has also expanded its HT 800 range for machining C-steels. The stable cutting wedge of the special indexable inserts ensures high wear resistance without increasing the process forces. The concave-shaped cutting edge ensures optimal chip breakage of long-chipping steels.

The indexable inserts delivered remarkable results:

- Market segment: Automotive

- Component Bushing

- Drilling depth: 24 mm, through-hole

- Diameter range: 19.5

- Material: C40

- Tool life: 6000 holes

- Tool life: 144 m

- Cutting speed Vc: 120 m/min

- Feed per revolution f: 0.35 mm/rev

The HT 800 consists of a wear-resistant steel beam, the replaceable cutting body and a locking screw with clamping principle. Thanks to the pin and fitting hole, the interchangeable insert has minimal play and sits firmly in the carrier. The innovative clamping principle achieves the highest process reliability for holes up to 10 x D. The clamping screws with screw lock improve the grip, even during machining with high vibration loads.

Reviews

There are no reviews yet.